The crack width for lower values of concrete cover or grade of steel while the Indian standard as well as the other expressions under estimates it as shown in figure 5.1, 5.2, 5.3. Figure 5.1.1: Estimation of crack width using different formulas compared with expt. Data for 20 mm cover. Normal crack width: f cu = 0.8 (0.85 f c?) = 0.68 f c? As above for skew cracking or skew reinforcement: f cu = 0.6 (0.85 f c?) = 0.51 f c? For skew cracks with extraordinary crack width – such cracks must be expected if modeling of the struts departs significantly from the theory of elasticity’s flow of internal forces: f cu = 0.4 (0.85 f.

Eurocode 2 part 1-1: Design of concrete structures 7.3 Crack control

The crack width, wk, may be calculated as follows:

| wk = sr,max⋅(εsm - εcm) | (7.8) |

where:

- sr,max

- is the maximum crack spacing

- εsm

- is the mean strain in the reinforcement under the relevant combination of loads, including the effect of imposed deformations and taking into account the effects of tension stiffening

- εcm

- is the mean strain in the concrete between cracks.

| (7.9) |

where:

see application for a rectangular section or application for a T-section

with

- Ecm

- the secant modulus of elasticity of concrete

fct,eff = fctm or lower, (fctm(t)), if cracking is expected earlier than 28 days

| = (As + ξ1⋅A'p)/Ac,eff | (7.10) |

with

| ξ1 = | (7.5) |

with

- ξ

- the ratio of bond strength of prestressing and reinforcing steel, according to Table 6.2

- ΦS

- the largest bar diameter of the reinforcing steel

- ΦP

- the diameter or equivalent diameter of prestressing steel:

Φp = 1,6⋅√AP for bundles, where AP is the area of a prestressing steel,

Φp = 1,75⋅Φwire for single 7 wire strands,

Φp = 1,20⋅Φwire for single 3 wire strands, where Φwire is the wire diameter.

kt = 0,6 for short term loading,

kt = 0,4 for long term loading.

• Where the bonded reinforcenlent is fixed at reasonably close centres within the tension zone (spacing ≤ 5(c + Φ/2), cf. Figure 7.2), the maximum crack spacing sr,max may be calculated as follows:

| sr,max = k3c + k1k2k4Φ / ρp,eff | (7.11) |

where:

k1 = 0,8 for high bond bars,

k1 = 1,6 for bars with an effectively plain surface (e.g. prestressing tendons).

k2

= 0,5 for bending,

= 0,5 for bending,k2 = 1,0 for pure tension.

Intermediate values of k2 should be used for cases of eccentric tension or for local areas:

| k2 = (ε1 + ε2)/(2ε1) | (7.13) |

where ε1 is the greater and ε2 is the lesser tensile strain at the boundaries of the section considered, assessed on the basis of a cracked section.

• Where the spacing of the bonded reinforcement exceeds 5(c + Φ/2) (cf. Figure 7.2), or where there is no bonded reinforcement within the tension zone, the maximum crack spacing sr,max may be calculated as follows:

| sr,max = 1,3(h - x) | (7.14) |

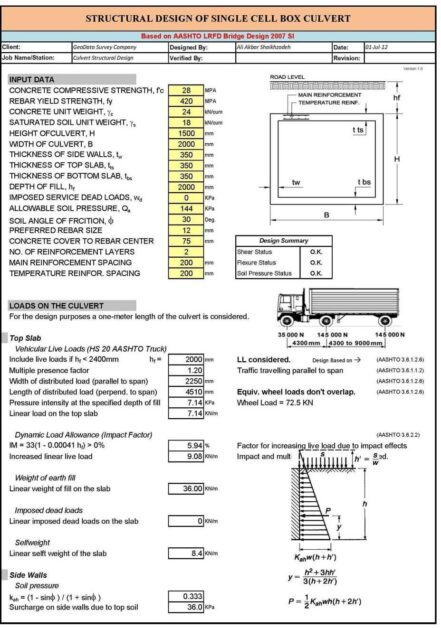

Crack Width Calculation Spreadsheet Example

where:

- h

- is the overall depth of the section (see Figure 7.1)

- x

- is the neutral axis depth of the section (see Figure 7.1).

This application calculates the crack width wk from your inputs. Intermediate results will also be given.

First, change the following option if necessary:

Crack Width Calculation Spreadsheet Template